We

are working dedicatedly in making a varieties of cast iron counter weights, cast iron slag pots, cast iron center columns or chimneys that cater to the needs of customers. Our high quality,

durable and reliable center columns are available in both one and two pieces

depends on how the end user is handling and their usages.

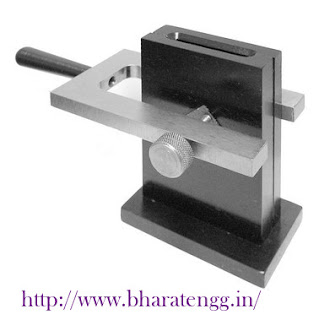

Bharat Engineering Works pvt. Ltd., we are the leading manufacturers, suppliers and

exporters of a range of Cast iron castings and s g castings using high quality

materials that are most effective and long lasting. We are using advanced

technology for our ferro alloys and metals. Our Cast iron center columns are

well-known for strength, reliable, corrosion resistant and ductility. We

offered these in different sizes and specifications as per the customer

requirements.

Features:

- Well strength

- Highly durable

- Outstanding finish

- Corrosion resistant

To know more >>> http://www.bharatengg.in/

Contact us : 9051568954

Mail us at: bharatengg@gmail.com